產(chǎn)品與服務(wù)

玻璃加工設(shè)備

立式全自動(dòng)除膜機(jī)

立式玻璃清洗干燥機(jī)

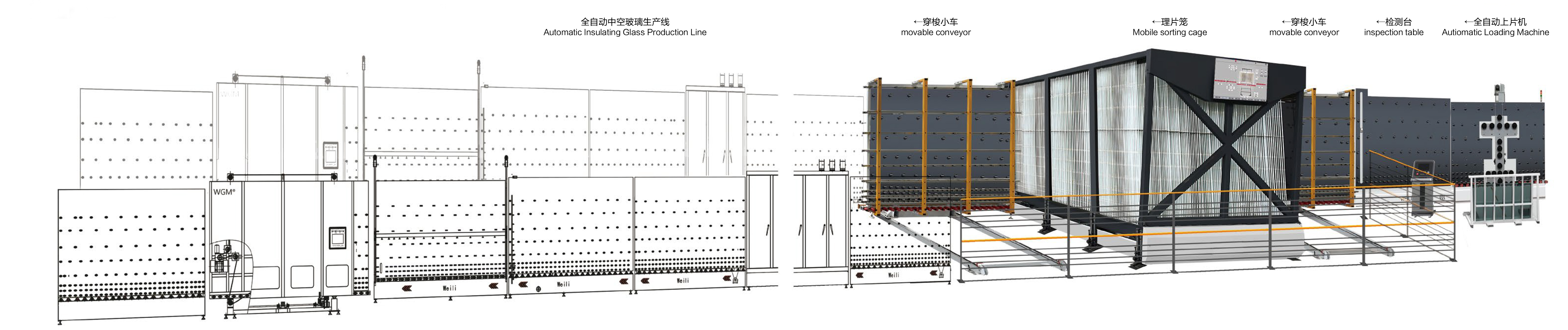

全自動(dòng)中空玻璃平壓生產(chǎn)線

數(shù)控玻璃鉆銑機(jī)

中空玻璃全自動(dòng)封膠線

鋁條折彎機(jī)

分子篩灌裝機(jī)

丁基膠涂布機(jī)

雙組分涂膠機(jī)

三臂多功能切割桌

回轉(zhuǎn)涂膠臺(tái)

軟隔墊自動(dòng)貼片機(jī)

玻璃轉(zhuǎn)角臺(tái)

玻璃吸盤吊架

玻璃全自動(dòng)上片機(jī)

中空玻璃全自動(dòng)下片機(jī)

玻璃清洗機(jī)(LOW-E)

其他設(shè)備

立式熱塑性間隔條中空玻璃生產(chǎn)線

理片籠

中空玻璃智能創(chuàng)儲(chǔ)系統(tǒng)