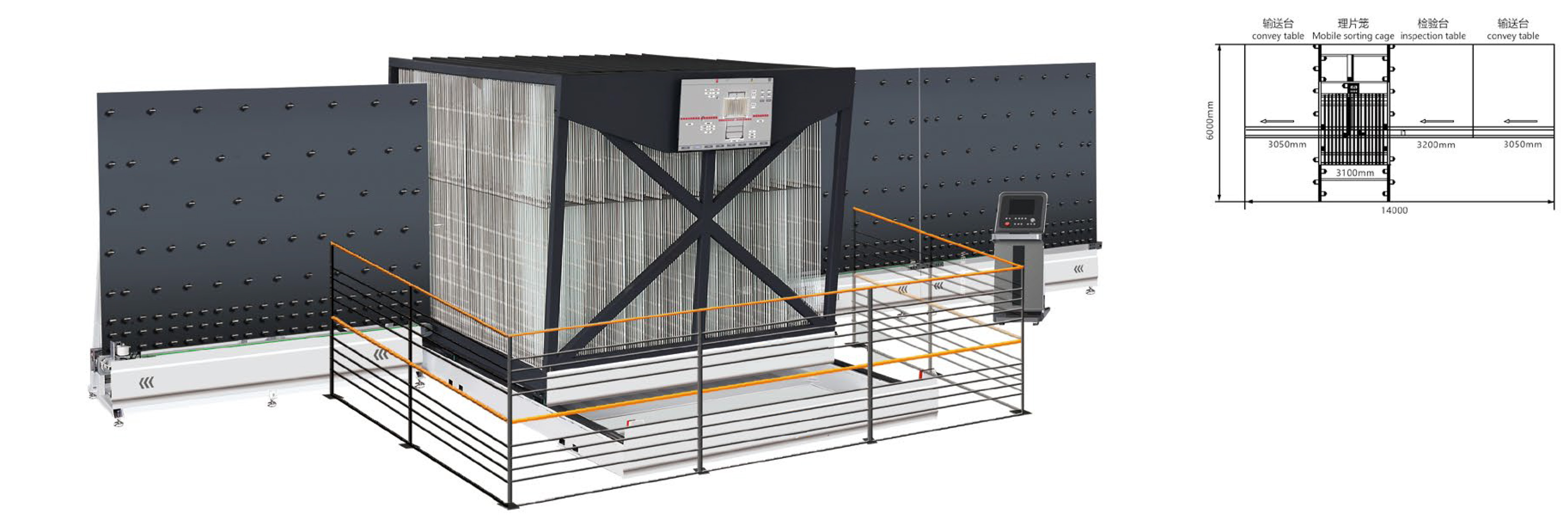

1.用于中空玻璃自動(dòng)分揀配對(duì),由立式輸送臺(tái)��、立式檢驗(yàn)臺(tái)、移動(dòng)理片籠以及立式輸送臺(tái)四部分組成���。

2.玻璃通過(guò)立式輸送臺(tái)運(yùn)送到檢驗(yàn)臺(tái)�����,系統(tǒng)能快速準(zhǔn)確檢驗(yàn)出玻璃尺寸�����,然后入庫(kù)�����,經(jīng)過(guò)智能比對(duì)后按規(guī)則配對(duì)出片��。

1.It is used for automatic sortin9 and matching of insulating gla!is.lt consists of four parts: verticalconveying table, vertical inspection table, mobile sorting cage alid vertical conveying table.

2.The glass is transported to the irspection station through the verticalconveyor table.The system can inspect theter intelligent comparison, it will be matchedglass size quickly and accurately,and then put it into the warehouse.Afand output according to the rules.

性能特點(diǎn)

(Main Feature)

1.完全取代了人工配片和貼標(biāo)���、撕標(biāo)過(guò)程,清理人工配對(duì)產(chǎn)生的錯(cuò)誤��。

2.用于中空線之前��,生產(chǎn)效率可提高25%-30%���。

3.支持掃碼功能����,省去檢驗(yàn)臺(tái)環(huán)節(jié)�����,直接掃碼確定玻璃配對(duì)信息。

4.減少人員需求:操作簡(jiǎn)單����,降低對(duì)人員技能要求。只需一人操作(擺放玻璃架)����,配合機(jī)械手上下片,無(wú)需人員值守�����。

5.一籠多片:相對(duì)市場(chǎng)同品�,理片籠可進(jìn)行1籠1片,或1籠2片的存儲(chǔ)模式�,最多可連續(xù)裝載180片(玻璃長(zhǎng)度小于1350mm)

1.It completely replaces the process of manual glass matching,labeling and tearing,avoiding errors caused by mqnual glass matching

2.It is used in front of insulating glass line,the production efficiency can be inceased by 25%-30%

3.Optional:support the code scanning function,save the inspection station steps,and directly scan the code to confirm the glass pairing information.

4.Reduced personnel requirements:It is easy to operate and reduces the skill requirements for matching workers.

Only need 1 worker to operate(place glass racks,replace empty racks),cooperate with macipulators to unload and unload glass sheet,and no workers are required to be on duty.

5.Multiple glass pieces in one cage:Compared with the similar products in the market,our sorting cage system can store 1 piece or 2 pieces of glass in one cage,and can load up to 180 pieces of glass continuously(glass length less than 1350mm)

技術(shù)參數(shù)

(Main technical parameter)

1.電壓(Power source):AC 380V 3ph 50HZ

2.功率(Total power):3.75kw

3.總重量(Total weight):2600kg

4.玻璃厚度范圍(Glass thickness):3~10mm

5.聯(lián)線功能(Connection function):12kw

6.傾斜角(Tilt angle):840

7.工作高度(Working High):550±30mm

8.籠體移動(dòng)速度(Movement speed):≤10m/min

9.傳輸速度(Transmit Speed):≤45m/min

10.壓縮空氣(Compressed air):800L/min

11.流量(Flow volume):0.8m3/ min

12.氣壓(Air pressure):≥8kgf/cm2

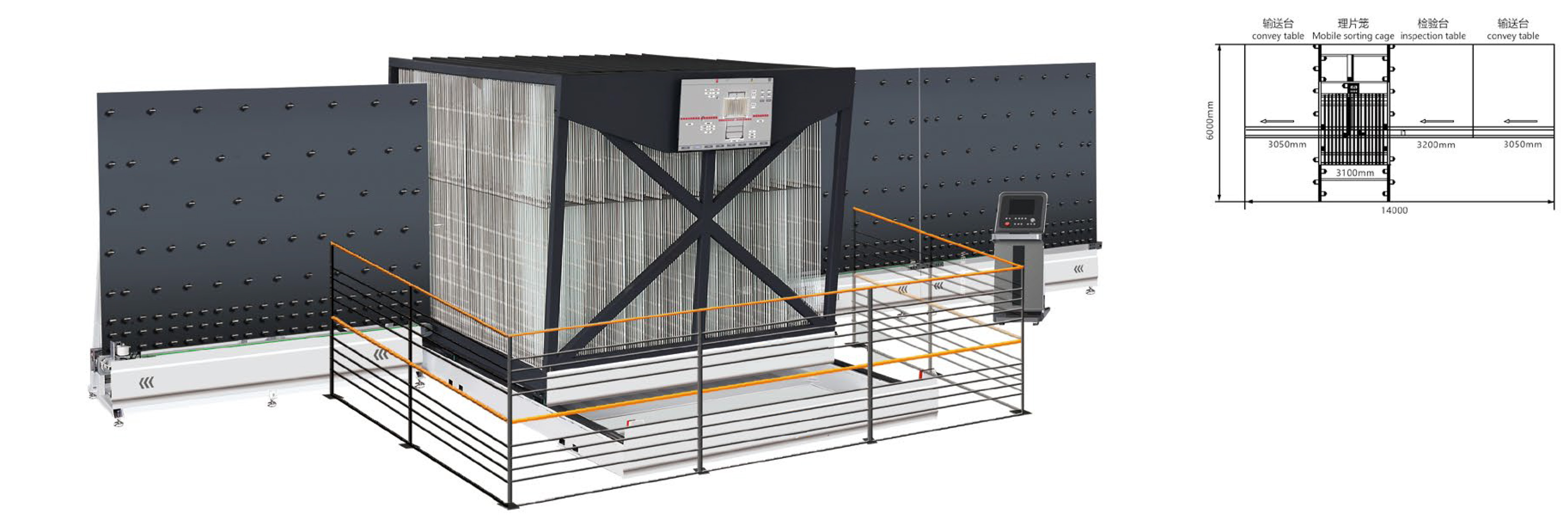

主要技術(shù)參數(shù)(Main Techniq ue Parameter) |

產(chǎn)品型號(hào) Product model | 最大玻璃尺寸mm Max.glass size | 最小加工尺寸 Min.Glass Size | 節(jié)拍 beat | 玻璃厚度 thickness | 傾斜角 Tilt angle | 籠數(shù) Cage Qty | 設(shè)備尺寸 L×W×H Dimension mm | 功能段 Function section |

WLPL2030 | 2000×3000 | 400×400 | 3~4 片/min | 3~10mm | 88° | 90/Cage | 14000×6000×2620 | 4 |

WLPL2530 | 2000×3000 | 400×400 | 3~4 片/min | 3~10mm | 84° | 90/Cage | 14000×6000×2620 | 4 |